Client Challenge:

A local customer approached Protomolecule after damaging a critical component on their high-performance Motocross E racing bike. The part—a finned casing panel that sits over the engine’s electronic board—was no longer available as a standalone replacement. The only option from the manufacturer was to purchase the full engine block at a cost of £5,000, which was impractical for the customer.

Our Solution:

The client shipped the damaged component to our workshop. Using our professional 3D scanning services, we digitally captured the exact geometry of the broken part. From there, our in-house CAD specialists reconstructed the missing geometry and repaired the damaged sections in design software—preserving critical fitting points and airflow channels.

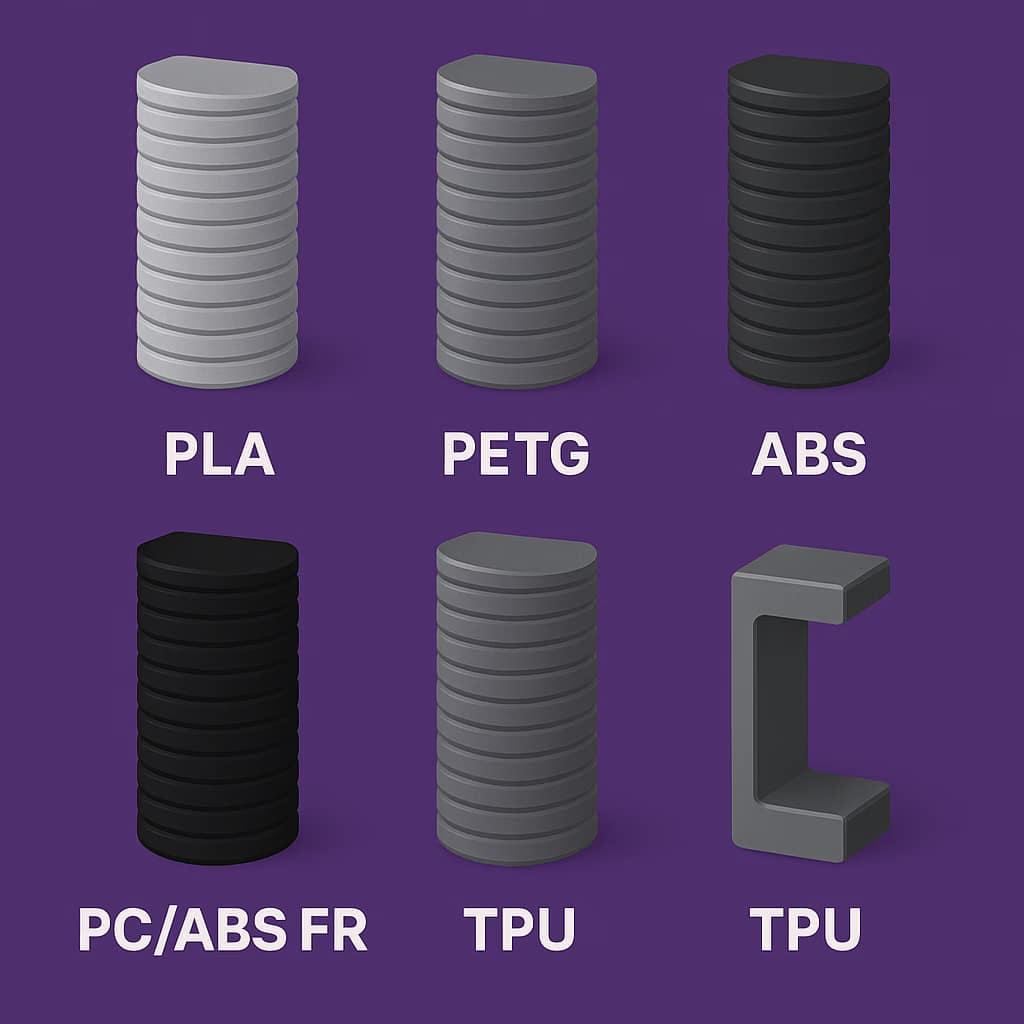

To aid in heat dissipation and maintain structural integrity, we selected a copper-infused PETG material for the final print. This material offers both durability and improved thermal conductivity, making it an ideal fit for high-performance applications like this one.

Outcome:

- The replacement part was produced at a fraction of the manufacturer’s cost.

- Heat performance was improved with copper-enhanced filament.

- The part fitted seamlessly and the client avoided having to replace the entire engine block.

- The client is now back on the track with confidence—and has since commissioned additional parts.