Client: Independent Toy Designer (UK)

Challenge:

Our client approached us after receiving a prohibitively expensive quote for injection moulding a spin toy they had developed. The high upfront tooling costs made it unviable for small-scale production. Seeking an alternative manufacturing solution, they turned to Protomolecule to explore the possibilities of 3D printing.

Our Solution:

The client sent us a physical sample of the toy. Using our advanced 3D scanning service, we captured the complete geometry of the original part, including fine tolerances and intricate detailing. The scanned mesh was then digitally cleaned and repaired in CAD software, preparing it for efficient batch production.

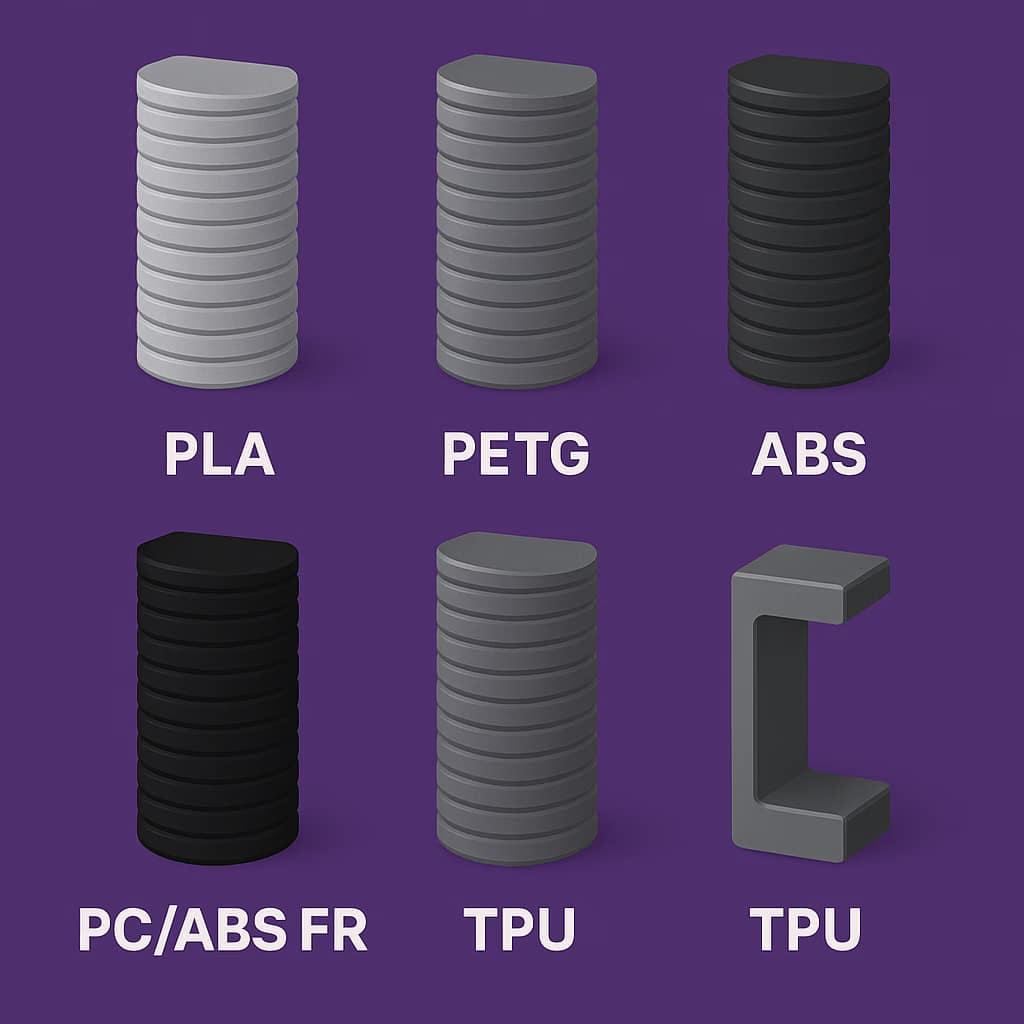

We recommended FDM printing in a durable, wear-resistant material suitable for frequent handling. Once approved, we began producing the parts in batches, delivering consistent quality while keeping production costs manageable.

Outcome:

The client received a high-quality, functional alternative to injection moulding without compromising on design integrity. Our batch production service enabled them to bring their spin toy to market without the high overheads of traditional manufacturing.

Highlights:

- Cost-effective alternative to injection moulding

- 3D scanned from original part

- Cleaned and prepped model for print-ready production

- Small-batch delivery with consistent quality