Client: Private Customer (UK)

Overview:

A customer needed a direct replacement for a Brompton folding bike seat collar. With no original spares easily available and no 3D model provided, they required a reliable print-only solution—quickly.

Challenge:

The part was essential for securing the seat post, meaning strength and fit were critical. No digital design was provided, and the customer simply needed two physical parts produced based on a sample.

Solution:

We used the sample part to produce two identical units using PETG, a material known for its strength, impact resistance, and weather durability—perfect for outdoor cycling applications.

Why Two?

The customer requested two units: one for immediate use and one as a spare for future redundancy. This ensured ongoing reliability without needing to re-order or wait if a replacement was needed.

Material:

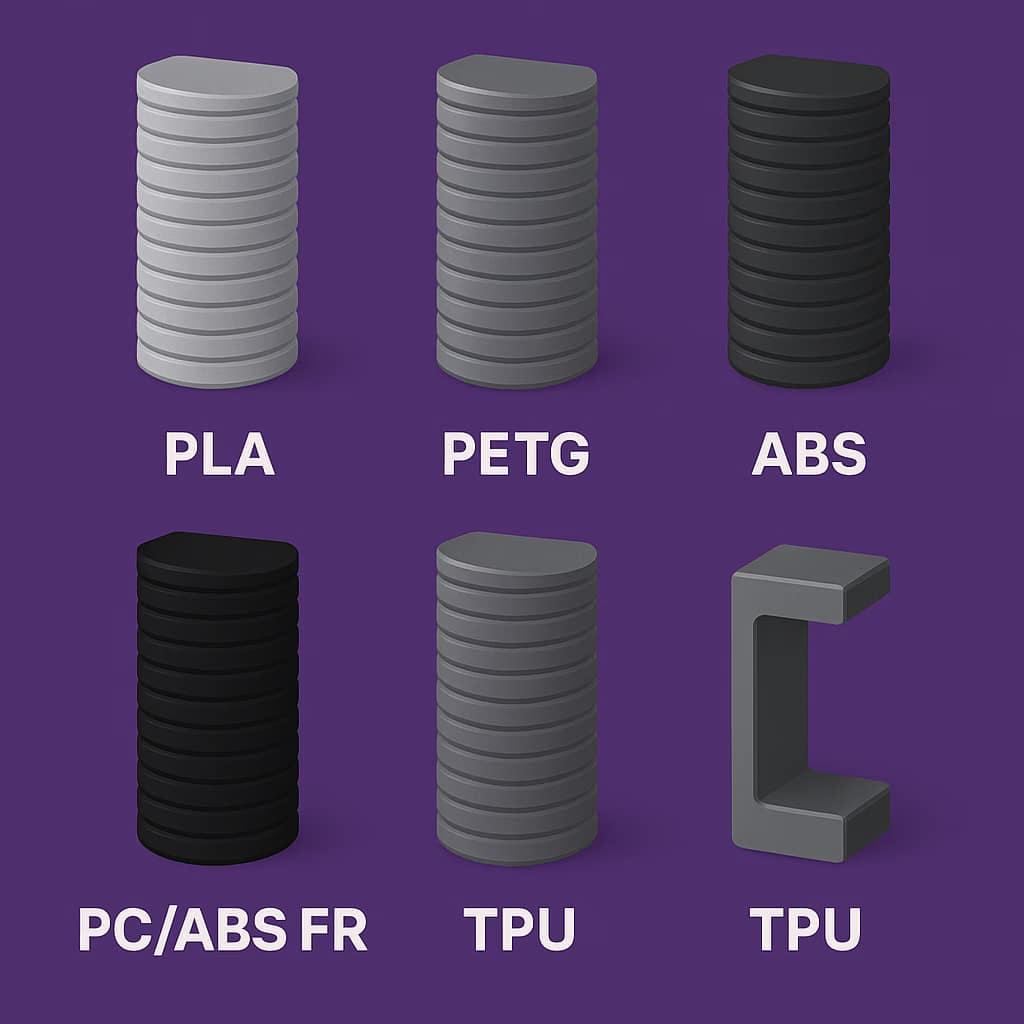

PETG – Ideal for mechanical applications. Offers strength, durability, and temperature resistance while remaining cost-effective.

Outcome:

Both parts were manufactured and shipped quickly. The customer was pleased with the results, especially the fit and quality, and appreciated having a spare on hand.