Client: Midlands Engineering Solutions (MES)

Location: Nottinghamshire, UK

Services Provided: 3D Design, Rapid Prototyping, 3D Printing

The Challenge

Midlands Engineering Solutions approached Protomolecule Ltd with an urgent need to prototype a custom mechanical part for a conveyor system. Their in-house team lacked the tools for rapid prototyping and needed a local 3D printing service in Mansfield that could deliver quickly and precisely.

The part had complex geometry and required tight tolerances to ensure compatibility with existing machinery.

The Solution

Our team began with a 3D scanning session of the broken part to capture its form and dimensions accurately. We then created a detailed CAD model in-house using our 3D design services, refining the structure for strength and durability.

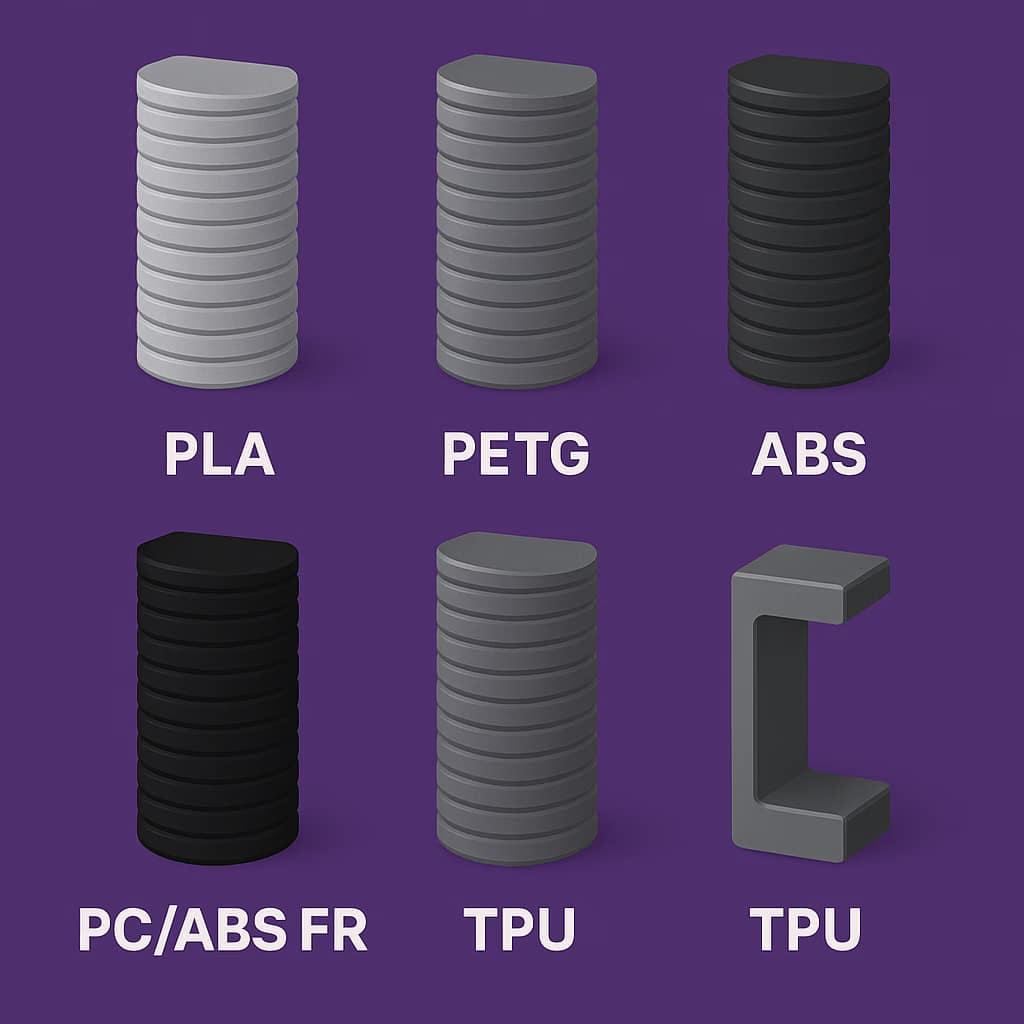

Using industrial-grade FDM 3D printers, we printed the prototype in PETG for its strength and flexibility. We offered several iterations over three days—leveraging our rapid prototyping services and on-demand 3D printing to meet their deadlines.

The Results

- Turnaround Time: 72 hours from scan to final prototype

- Cost Reduction: 65% cheaper than traditional machining

- Functionality: 100% fit and operational with the client’s system

- Client Satisfaction: “Protomolecule’s speed and precision helped us get production back on track. A brilliant local service.” – MES Technical Manager