At Protomolecule, one of the most common questions we get from clients—whether they’re hobbyists, engineers, or product designers—is: “What material should I use for this print?”

The answer isn’t always straightforward. Different projects have different demands, and the right filament choice can make all the difference between a successful, durable print and a failed prototype. In this blog, we’ll explore the most common materials we use and when to choose them.

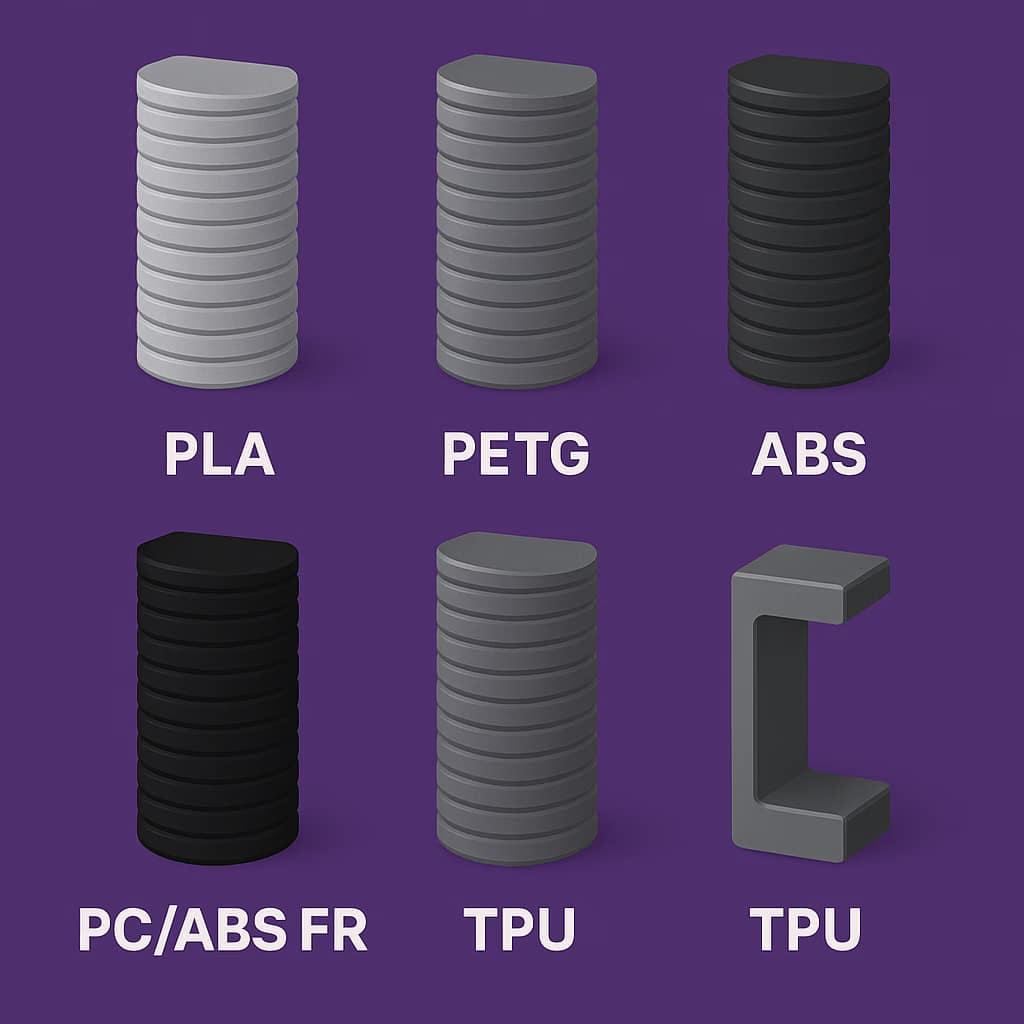

PLA – Best for Fast, Low-Cost Prototypes

PLA is one of the most commonly used filaments in the industry due to its ease of use, low cost, and reliable printability. It’s perfect for visual models, early prototypes, and quick turnaround projects. However, it lacks strength and heat resistance, so it’s not ideal for functional or outdoor parts.

PETG – Durable & Weather-Resistant

PETG offers a balance of strength, flexibility, and chemical resistance. It’s our go-to choice for functional parts that need to withstand stress or be used outdoors. PETG is also food-safe in some contexts and has better impact resistance than PLA, making it great for practical applications.

ABS – Strong & Heat-Resistant

ABS is widely used in engineering applications due to its strength and high heat resistance. However, it does require a controlled print environment to prevent warping. At Protomolecule, we often print ABS parts inside heated enclosures for best results.

PC/ABS FR – For Industrial & Safety-Critical Applications

Some jobs require compliance with fire retardancy standards—especially in the transport or construction sectors. We print with specialised PC/ABS FR blends for these use cases, using actively heated chamber printers to maintain quality and strength. This material is ideal for electrical housings, automotive components, and train interiors.

TPU – Flexible & Impact-Resistant

When flexibility is key, TPU is our filament of choice. It’s great for gaskets, protective housings, or anything requiring a rubber-like material. TPU is more challenging to print due to its flexibility, but with the right printer tuning, it produces incredibly durable results.

Why Material Choice Matters

Every project has a unique use case—whether you’re developing a product for market, building a prototype for pitch meetings, or producing low-volume functional parts. Choosing the right material affects not just the performance, but also the longevity, cost, and feasibility of the print.

At Protomolecule, we don’t just print—we advise. When you come to us with an idea, we’ll walk you through the best filament choices based on your goals, your deadlines, and your budget.

If you’re unsure which material is right for your next print, get in touch. Our team is here to help guide you through the entire process—from design to delivery.