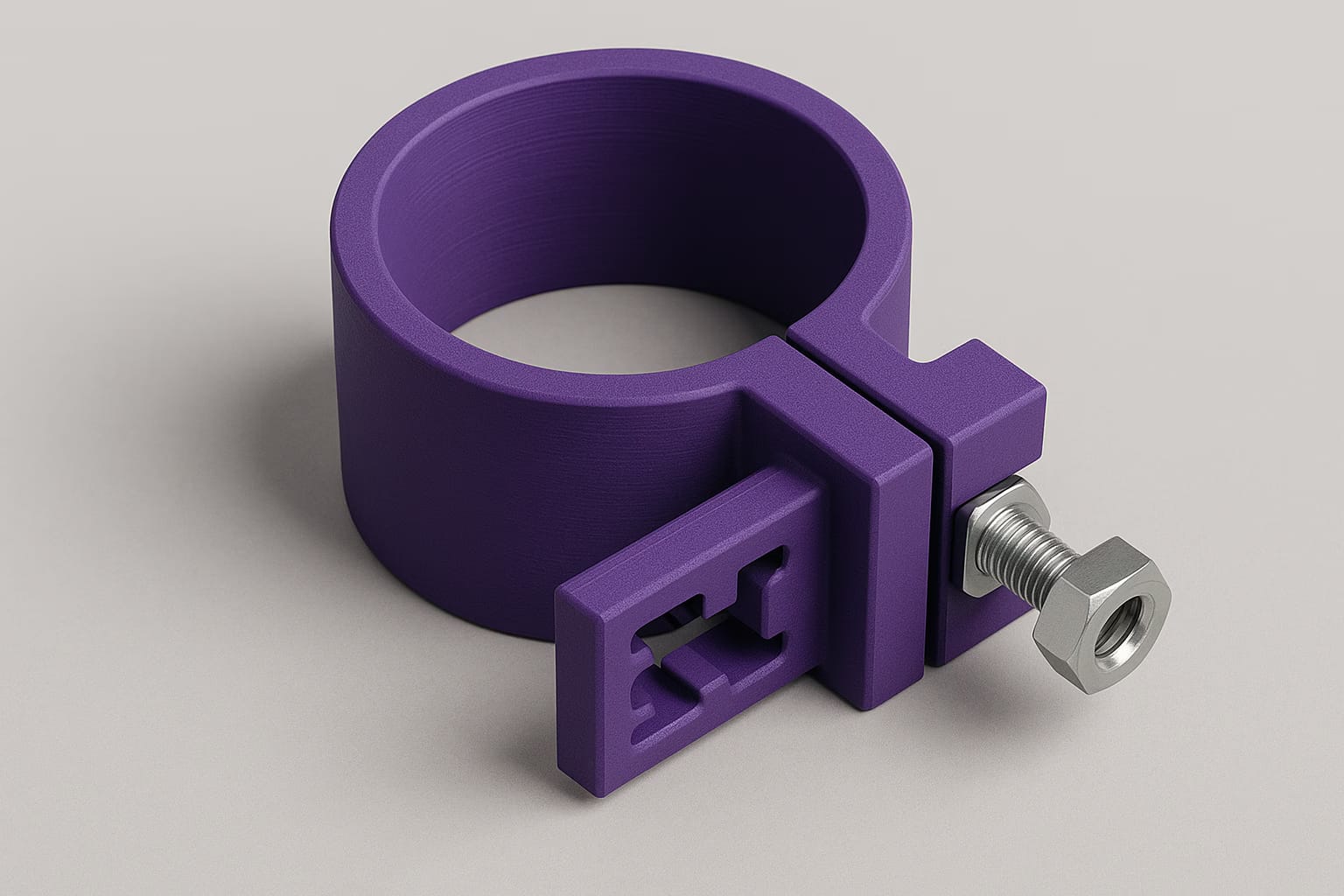

At Protomolecule, we were recently approached by a local Nottinghamshire-based gutter vacuuming company with a specific challenge: they needed a robust clamp system to attach equipment securely to a 3030 aluminium extrusion framework. Off-the-shelf solutions weren’t fit for purpose—either too bulky, expensive, or not quite the right fit.

Understanding the Problem

The client needed a 50mm clamp that would:

- Fit snugly around round tube

- Attach to 3030 aluminium extrusion

- Be both strong and lightweight

- Withstand repeated use in a demanding commercial setting

With no prior CAD model available, our team designed the part from scratch to meet their functional requirements and fit tolerances precisely.

Our Approach

- Custom CAD Design: We developed a 3D model tailored to the extrusion’s profile and the clamp’s required grip range.

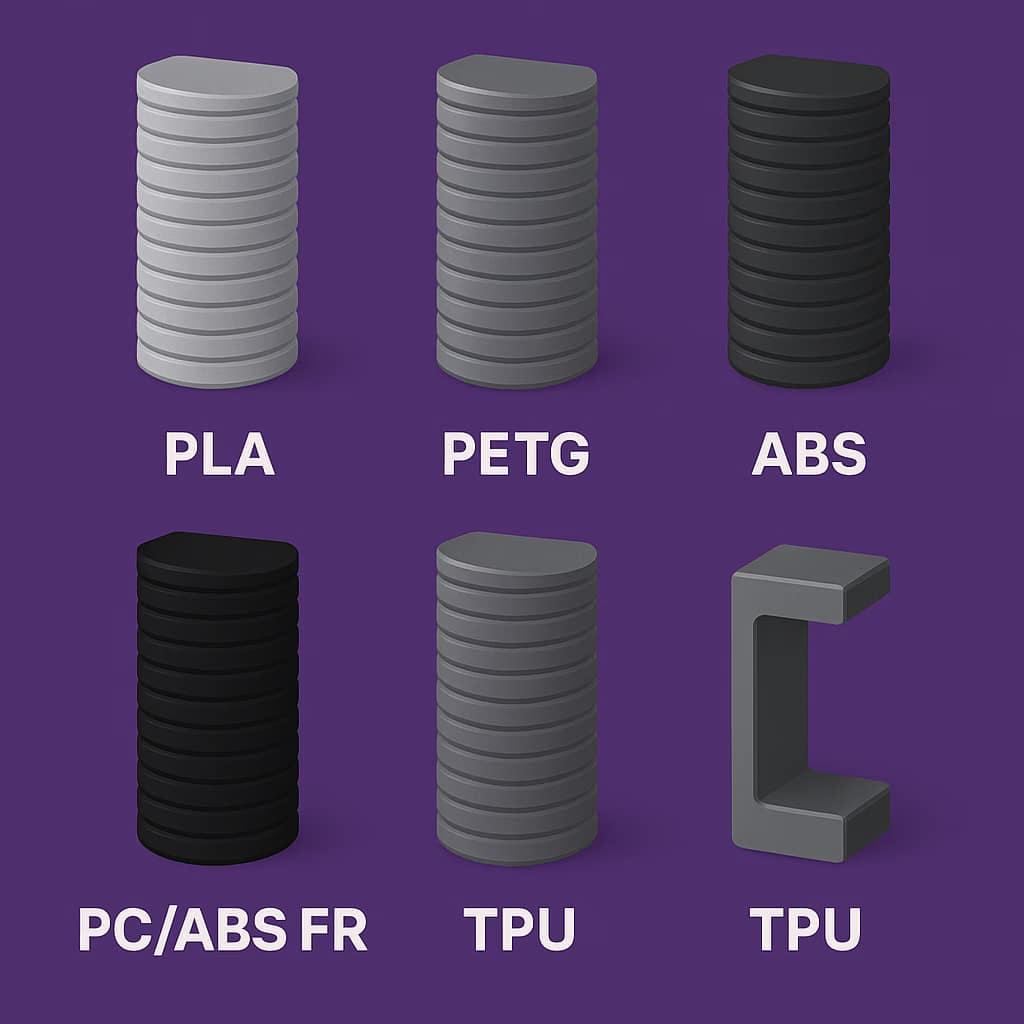

- Material Selection: PETG was chosen for its durability and flexibility, offering a good balance between strength and ease of use.

- Prototyping and Testing: A prototype was printed and tested on-site by the client to confirm fit and functionality.

Outcome

The final product was delivered quickly, performing exactly as required. The client now has a reliable clamping solution for their equipment—without needing to modify their existing framework or invest in metal fabrication.