Client: Local Nottinghamshire Engineering Company

Service: Advanced 3D Printing – Functional Prototyping in PC/ABS-FR

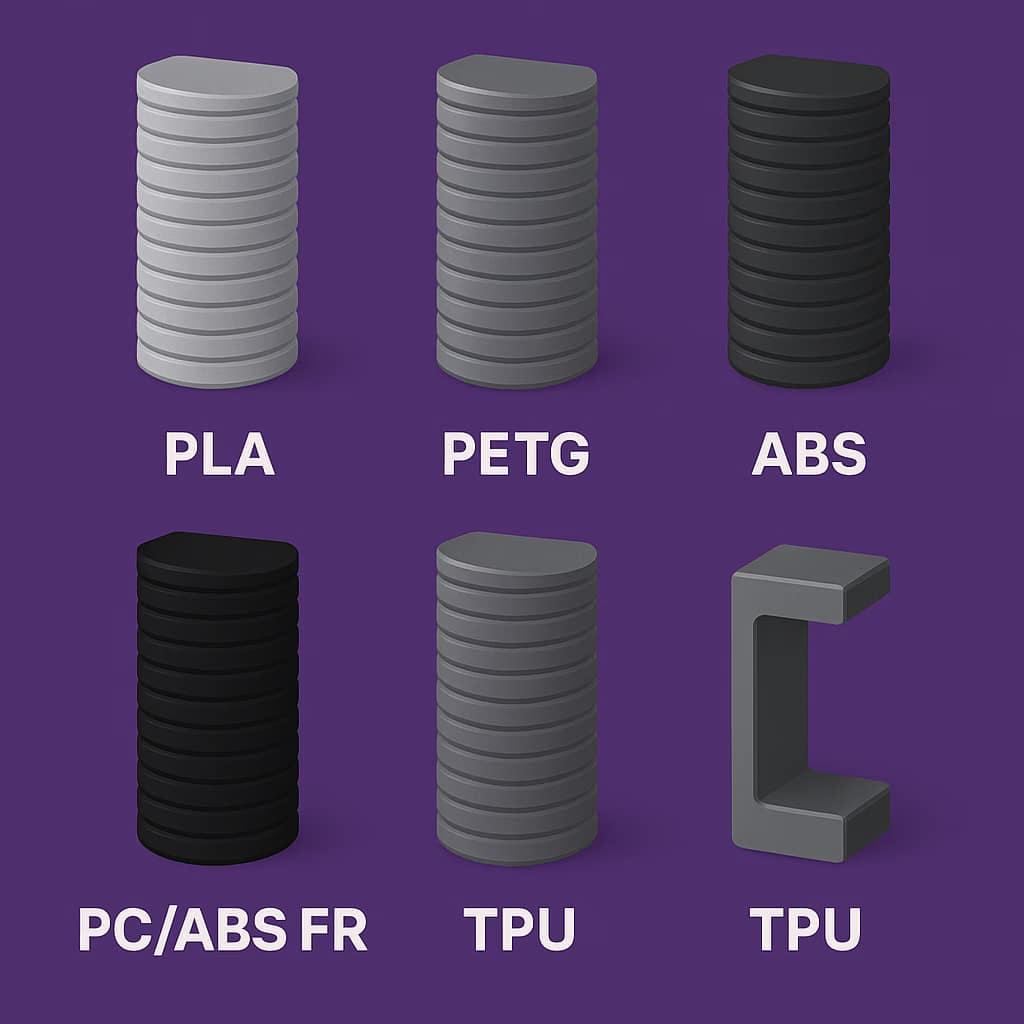

Material: PC/ABS-FR (Flame Retardant)

Printer Requirements: Actively Heated Chamber

The Challenge

A local engineering company approached Protomolecule with an urgent need: they required a durable, flame-retardant component produced quickly and reliably. Their usual supplier was struggling to meet both the required tolerances and lead times—putting the client’s own production schedules at risk.

The Solution

We sourced PC/ABS-FR filament, a high-performance engineering thermoplastic known for its strength, thermal resistance, and flame retardancy (FR). Commonly used in automotive and electrical applications, PC/ABS-FR meets UL94 V-0 ratings, making it ideal for environments requiring strict fire safety compliance.

Printing this material isn’t simple—it demands a printer with an actively heated chamber to maintain optimal thermal conditions throughout the process. Fortunately, our farm of high-spec machines is up to the task.

The Result

Within days, we:

- Designed the part to spec in CAD

- Validated tolerances

- Printed in PC/ABS-FR using controlled high-temperature settings

- Delivered a ready-to-use part that outperformed expectations

The client now relies on us for ongoing production runs, confident that Protomolecule can meet both the technical and logistical demands.