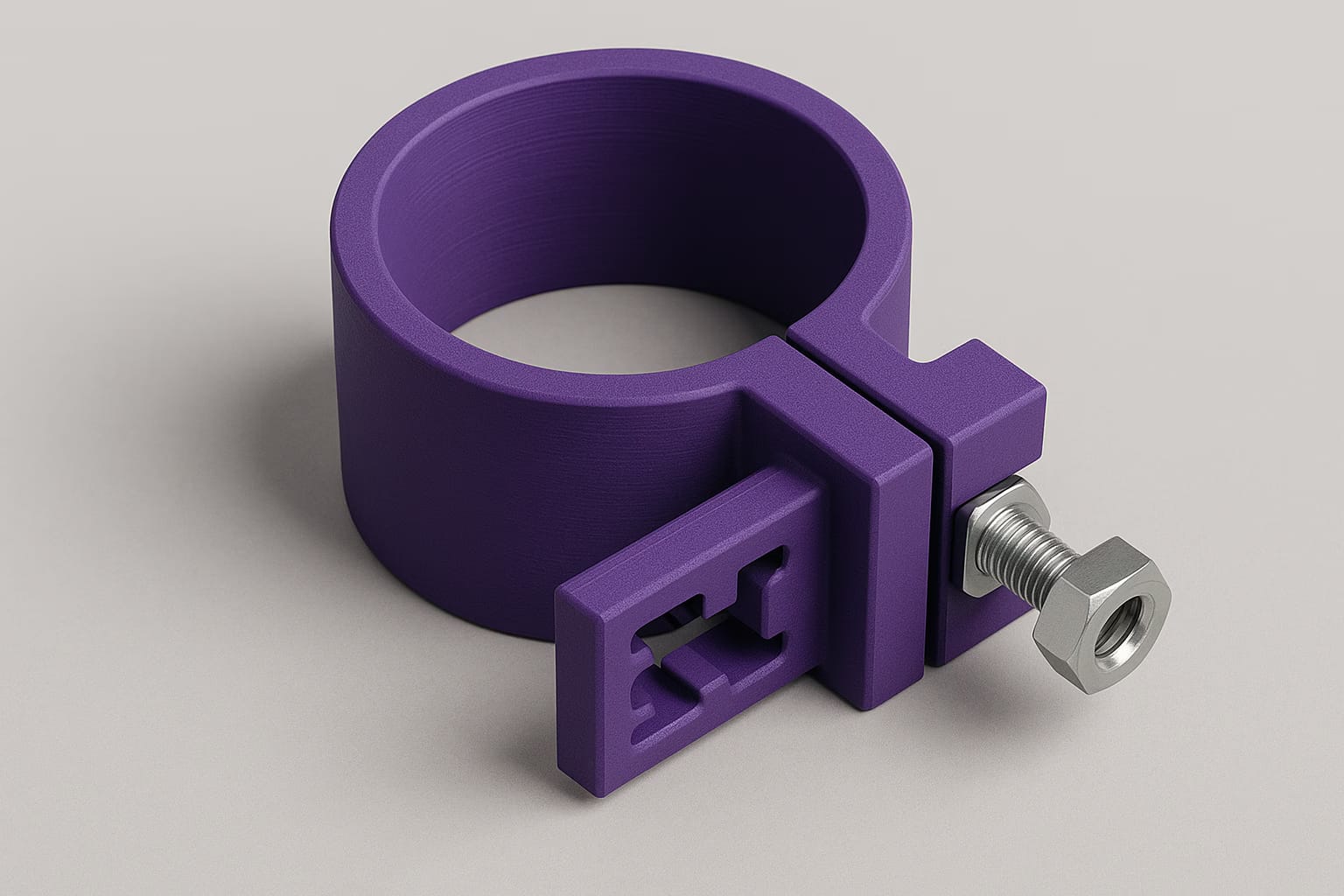

A transport sector client based in Derbyshire approached us needing 120 replacement seat arm components for use on passenger trains—with a tight deadline and strict material requirements.

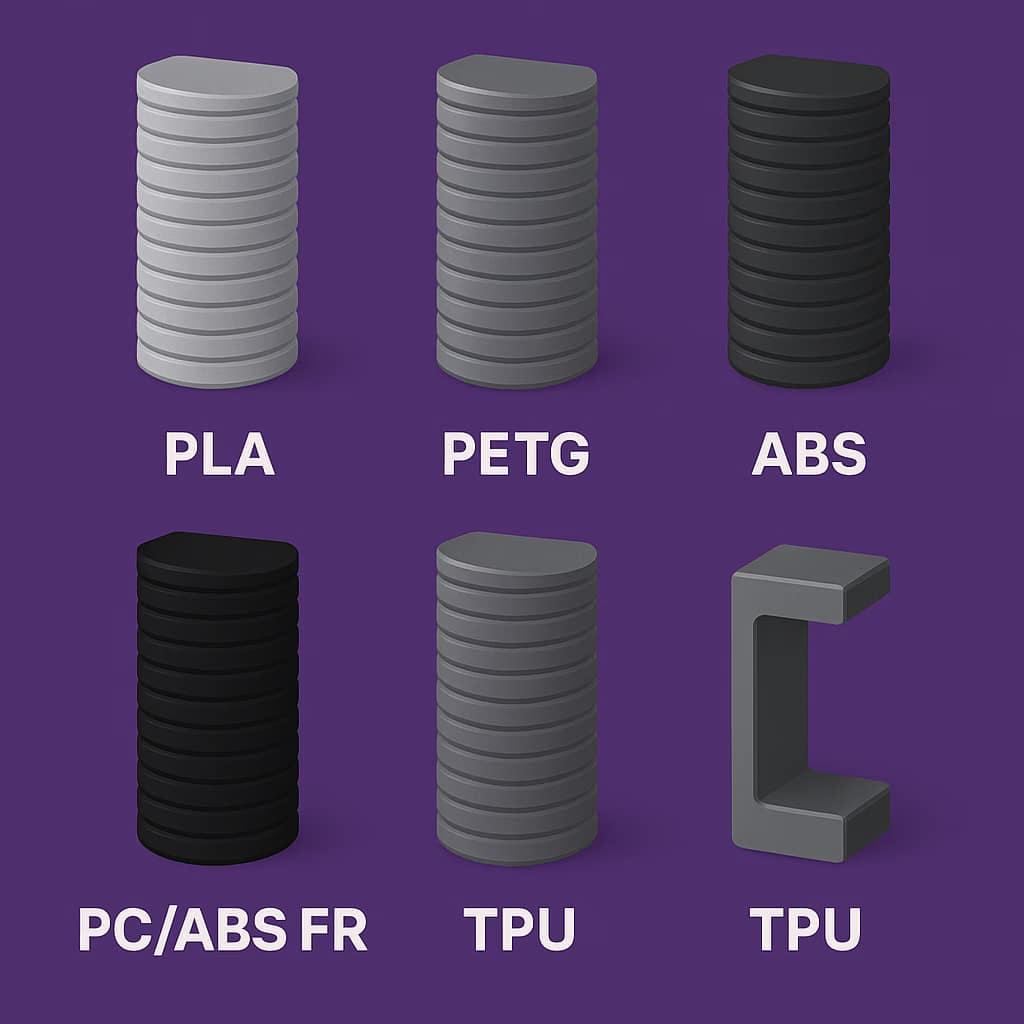

These components were to be printed using a fire-retardant composite material, suitable for use in regulated public transport environments. The client supplied the 3D files, requiring no design or modification, just reliable and consistent production.

Thanks to our high-capacity print farm and extensive experience with FR-rated materials, we were able to source the specialist filament, then print and dispatch all 120 units within just 5 days—meeting the client’s deadline without compromise.

This project highlights our ability to scale batch production quickly using specialist materials—even under pressure.