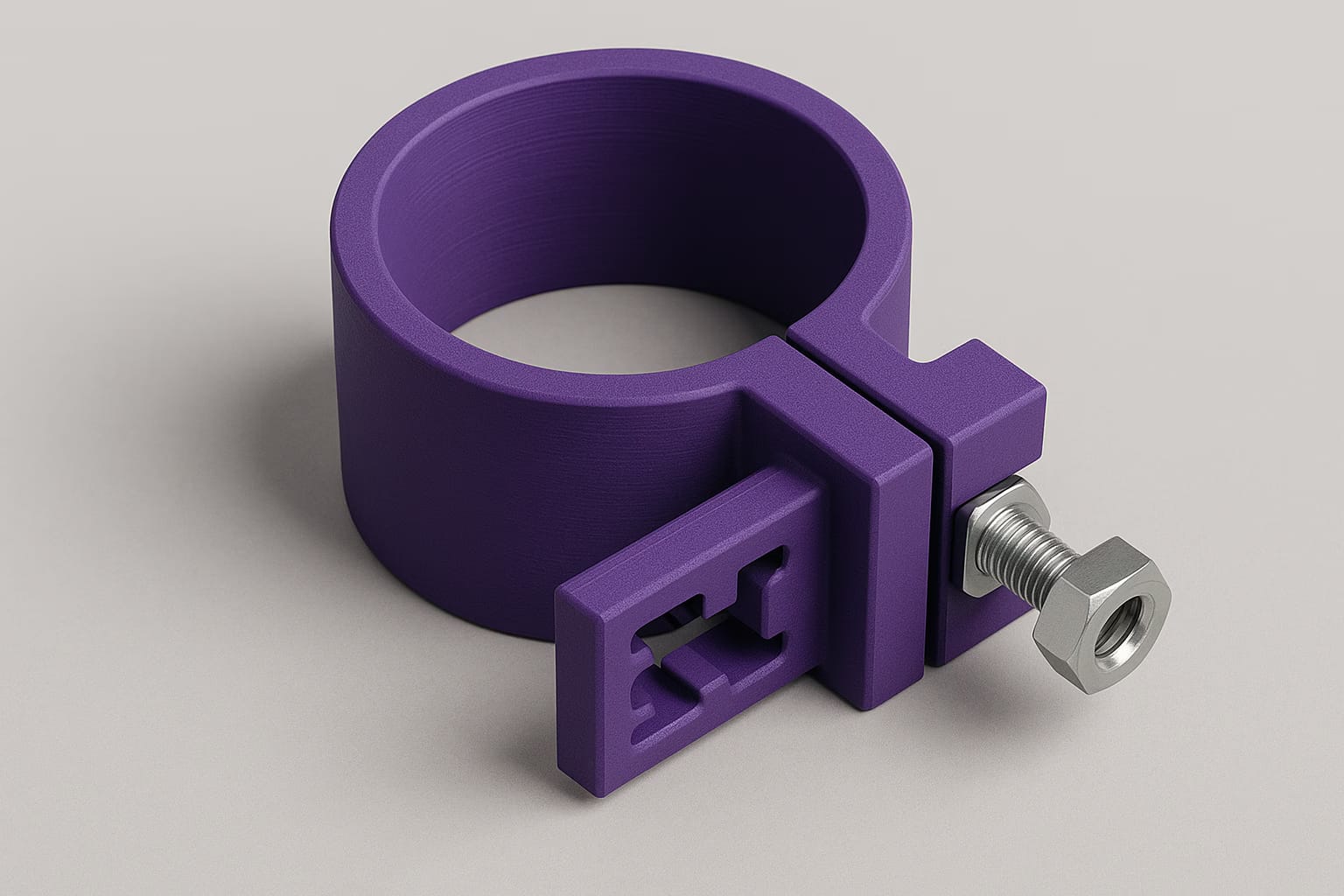

We were recently approached by a CNC machining company that required a highly accurate digital model of a spindle component for reproduction. The original part needed to be scanned in detail and converted into a CAD-compatible format suitable for their internal workflow.

Using our high-resolution 3D scanning equipment, we captured every contour and geometric feature of the spindle. Once scanned, the raw mesh data was processed and converted into a clean, watertight 3D model. As requested by the client, we exported the final file in .iges format — a neutral CAD file type commonly used in precision manufacturing and CNC environments due to its broad compatibility with various software packages.

This project is a perfect example of how our 3D scanning service supports local manufacturers by simplifying the reverse engineering process, saving both time and cost while ensuring production readiness.